In this article

- The Need for a Supplier Risk Scoring Model

- What is a Supplier Risk Scoring Model?

- Transforming your Supplier Risk Scoring Model

- 4 Reasons Why Organizations Advance their Supplier Risk Scoring Model

- The Modern Risk Assessment Workflow

- What Insights do Supplier Risk Scoring Models Provide?

- How can you Identify Risky Suppliers?

- How you can Build a Risk Model or Upgrade your Existing One

In this article

- The Need for a Supplier Risk Scoring Model

- What is a Supplier Risk Scoring Model?

- Transforming your Supplier Risk Scoring Model

- 4 Reasons Why Organizations Advance their Supplier Risk Scoring Model

- The Modern Risk Assessment Workflow

- What Insights do Supplier Risk Scoring Models Provide?

- How can you Identify Risky Suppliers?

- How you can Build a Risk Model or Upgrade your Existing One

Organizations looking to improve how they evaluate new suppliers can benefit from transforming their decision-making process. This blog focuses on the initial assessment of supplier risk and particularly on the value of an automated Supplier Risk Scoring Model. We will explore inherent risk and how an aligned and capable scoring model that focuses effort on where needed will realize significant benefits to your organization.

Beyond initial risk assessment, transforming how residual risk is evaluated particularly with the help of AI, can further reduce compliance workloads while maintaining human oversight and control. While this blog focuses on inherent risk, residual risk evaluation presents another valuable opportunity for transformation.

The Need for a Supplier Risk Scoring Model

The objective of supplier risk scoring is simple: determine how much risk a supplier brings to your business. Onboarding a low risk supplier is highly desirable as opposed to onboarding one with high risk! High-risk suppliers must be prevented from breaching your inner circle or consciously accepted with full understanding of the risks exposed. Inadvertently onboarding high-risk vendors can expose your business to significant risk! Onboarding teams are the first, and most critical, line of defense. However, determining which suppliers are good, and which are bad, is difficult.

The first barrier in your defense line is the speed, ease, and effectiveness of understanding inherent risk exposure. This is a critical metric for teams, as it drives all downstream processes. This inherent risk assessment is important, but it’s often slow and generalized – leaving everyone frustrated when low-risk suppliers are obviously delayed. Does this sound familiar? These are static, inefficient, bureaucratic processes that are slowing down your business and costing you money.

Establishing or upgrading your Inherent Risk Model supports your onboarding teams by providing a reliable, accurate and robust supplier scoring framework. This delivers confidence, traceability, and structure to your next supplier onboarding actions and provides confidence to decision makers in every step of the process.

In today’s global climate, where organizations are dealing with dispersed and uncertain global supply chains – every tool matters to increase risk awareness and provide consistency and confidence. The cost of realized supply-chain risks are crippling organizations that have failed to adapt their risk-scoring processes into a formalized, modern, digital asset. Under-compliance hurts, but over-compliance also has significant adverse consequences. Over-burdening suppliers (and your internal team) with unnecessary compliance requirements and assessments can cloud risk focus and also result in poor supplier engagement potentially inflicting much pain in the supplier relationship.

Implementing an automated Supplier Scoring Model will streamline up your entire supplier onboarding and re-assessment processes not only making them faster and more efficient but critically more effective. Incorporating scaled-risk profiles into the model will onboard low risk suppliers with significantly lower effort and target work at high-risk suppliers, products and services. The new imperative is to provide Internal teams with automated intelligent processes that include improved structure, better workflows, AI assisted risk evaluation and leading analytics. Less work for vastly improved outcomes – now that’s a win-win.

Let’s see how leading organizations are choosing to structure their supplier risk scoring models – and how this is empowering them with confident, actionable insights. Now let’s focus on Supplier Inherent Risk – the Front Door to supplier risk assessment.

What is a Supplier Risk Scoring Model?

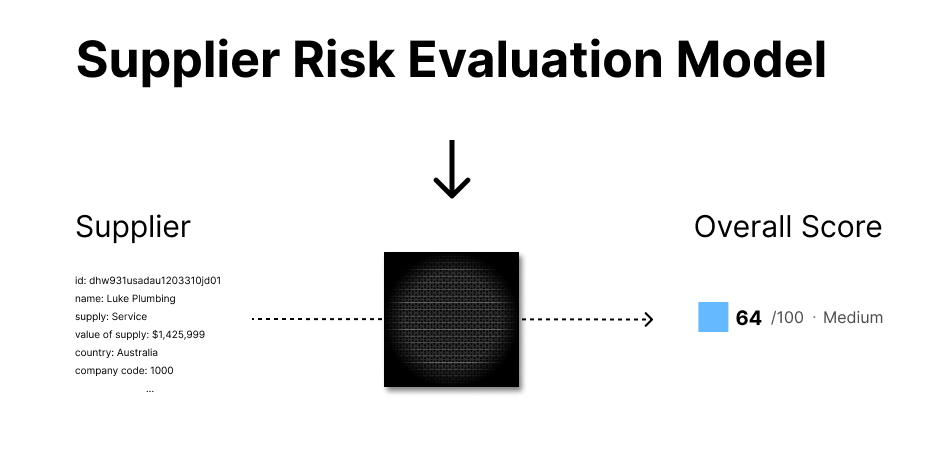

A Supplier Risk Scoring Model is the structured, quantitative framework used to evaluate supplier risk to an organization. It can take many forms, but the most effective is a digital matrix that allows you to pass in supplier and supply information (and any additional assertions) and derive a score for each of your considered risks.

The simplified structure of a Supplier Scoring (Evaluation) Model.

Supplier Risk Scoring Model Components

The following are the key components of a risk scoring model:

- Risk Types – The specific categories of risk considered in the assessment.

- Risk Thresholds – The acceptable levels of risk defined for each risk type.

- Supplier Profile – Attributes that influence risk, including whether the supplier is critical or major, along with details provided by the supplier and requestor.

- Supply Profile – Information about the goods or services being supplied.

- Contract Profile – The size and duration of the contract, which affect exposure.

- Inherent Risk – The baseline level of risk present before any controls or mitigation.

- Matrix Model – Connects supplier, supply, and contract data to relevant risk types.

- Model Engine – Calculates the overall supplier risk score by weighting and combining input factors across risk categories to generate a comprehensive risk profile.

The objective of the scoring model is to provide a quantitative inherent risk profile for supplier engagement. The components of the model, matrix and engine all work with the data inputs to calculate and assess the exact shape these risks take and propose the required set of additional actions where the inherent risk exceeds the threshold risk. Most often these additional actions take the form of supplier risk self-assessment questionnaires designed to better understand and evaluate the risk to determine the remaining residual risk.

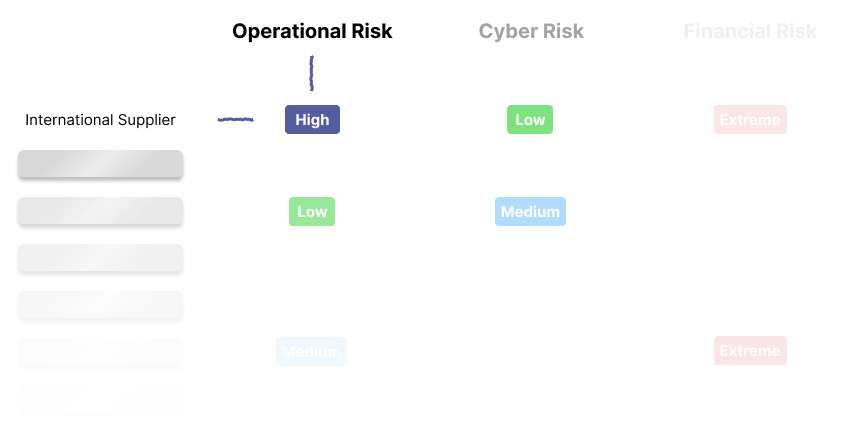

The risk matrix should relatively rank supplier inputs to your configured risks.

Transforming your Supplier Risk Scoring Model

When Should I Transform?

Regardless of size, budget, or supplier base – if you’re working with business partners to get stuff done, you should construct or formalize your Supplier Risk Scoring Model as a priority.

This process is not budget, effort, or team constrained. The basic concepts can be implemented quickly with off-the-shelf models. These may remain sufficient over the short term but should be finetuned to your exact business requirements and acceptable levels of risk as soon as possible.

Why Should I Transform?

The formalization of a Supplier Risk Scoring Model brings a risk-first attitude to supplier management. When suppliers are onboarded or re-assessed, collected, and derived data is used to support the inherent risk evaluation process.

4 Reasons Why Organizations Advance their Supplier Risk Scoring Model

1) More Effective Risk Evaluation

The most important aspect of a Supplier Risk Scoring Model is that it delivers more effective evaluation. It achieves this by reducing subjectivity and utilizing advanced calculations for risk profiles.

2) Reducing Work for Suppliers

By designing a Supplier Risk Scoring model correctly, you reduce downstream workload for suppliers by streamlining the tasks that you require them to do, exclusively based on their inherent risk-exposure. Ineffective upfront risk determination results in a bundling of risk questionnaires to all suppliers leading to frustration for everyone. All requests for information and work for suppliers should be automatically derived by the model based on their relative scores (inherent vs threshold) against each risk type.

3) Reducing Work for your Team

By generating a digital model and maintaining settings to only target high risks, overall effort by suppliers is significantly reduced. This has the knock on effect of significantly reduced work for the internal teams. Nearly all of the repetitive, mistake-prone, manual tasks are eliminated!

4) Empower Internal Teams by Providing a Strong Framework and Eliminating Inter-rater Variances

Decision makers are empowered by both strong quantitative and objective qualitative data. This delivers confidence and useful evidence for decision makers to make informed, timely decisions.

The Modern Risk Assessment Workflow

Whether you conduct pre-qualification risk assessments or a single pre onboarding assessment, best practice risk assessment process contains the following long standing principles and workflow:

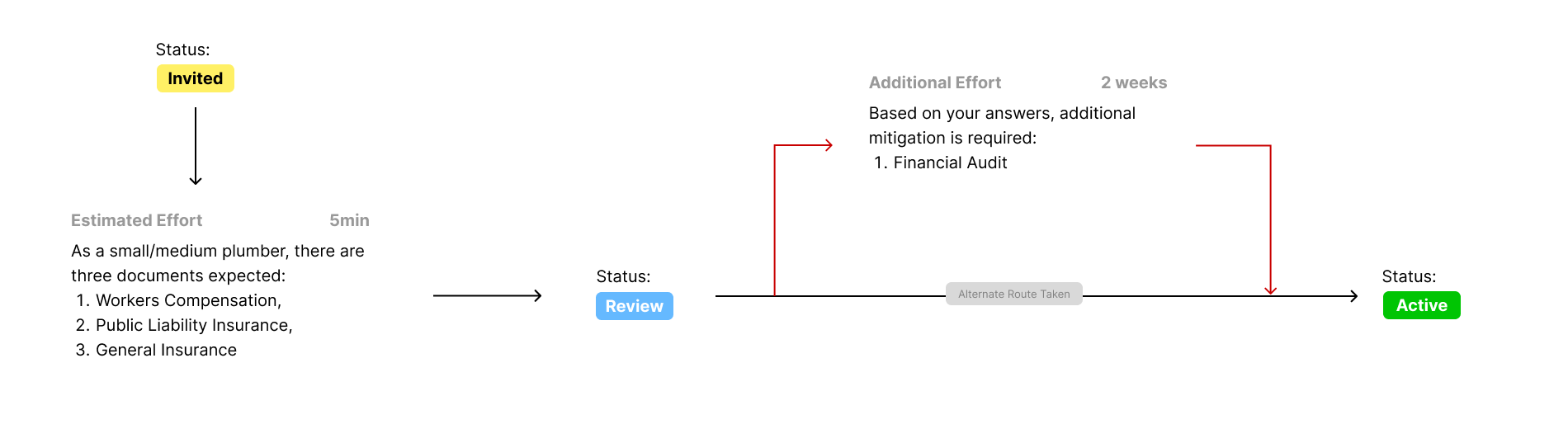

Inherent Risk

Before onboarding a new supplier (or during re-assessment) – the inherent risks associated with the supplier and contract need to be identified. This will drive the downstream risk assessment processes. This is where a Supplier Scoring Model is highly advantageous and should be used.

Initial Risk Assessment

Based on the initial risk identification, a list of further qualification questions can be asked to further refine the focus areas of concern. Based on all the initial information the appropriate certificates and supplier risk questionnaires are assigned. The answers to these will act as mitigations and will result in either a decrease or increase in final risk assessment.

Supplier Risk Assessment Questionnaires

The supplier answers the questionnaires and provides documents and certificates. As a result of a streamlined initial risk assessment processes, the resulting information collection is specific and directly related to the type of supply being provided and the associated risk to the customer. The goal is to obtain all of the required information in the quickest, easiest way possible.

Evaluation of Supplier Risk Assessments

Based on the provided risk mitigation and exposure-evaluation documents, a risk assessment must be made on the returned documents. High risk is attributed to unfavorable results. Intelligent document management systems (whether inbuilt to your tooling or third-party) should allow you to apply automated document analysis. If there is an expected answer for a question that the supplier has answered differently – it should be highlighted and assessed.

You may discover (at any point, even after approval) that additional risk mitigations are required. The workflow will in this instance return to step 3 – Risk Mitigation.

Sometimes alternative routes are required before approval is provided. Automated workflows should handle this.

Residual Risk Approval Gate

The risk evaluation process will result in a final determination of the risk level (in this case a score) known as the residual risk. The final and most important step is for the business decision makers to:

- Accept the risk and approve onboarding (immediately),

- Reject onboarding based on excessive risk for the potential benefit, or

- Seek further information or risk mitigation measures.

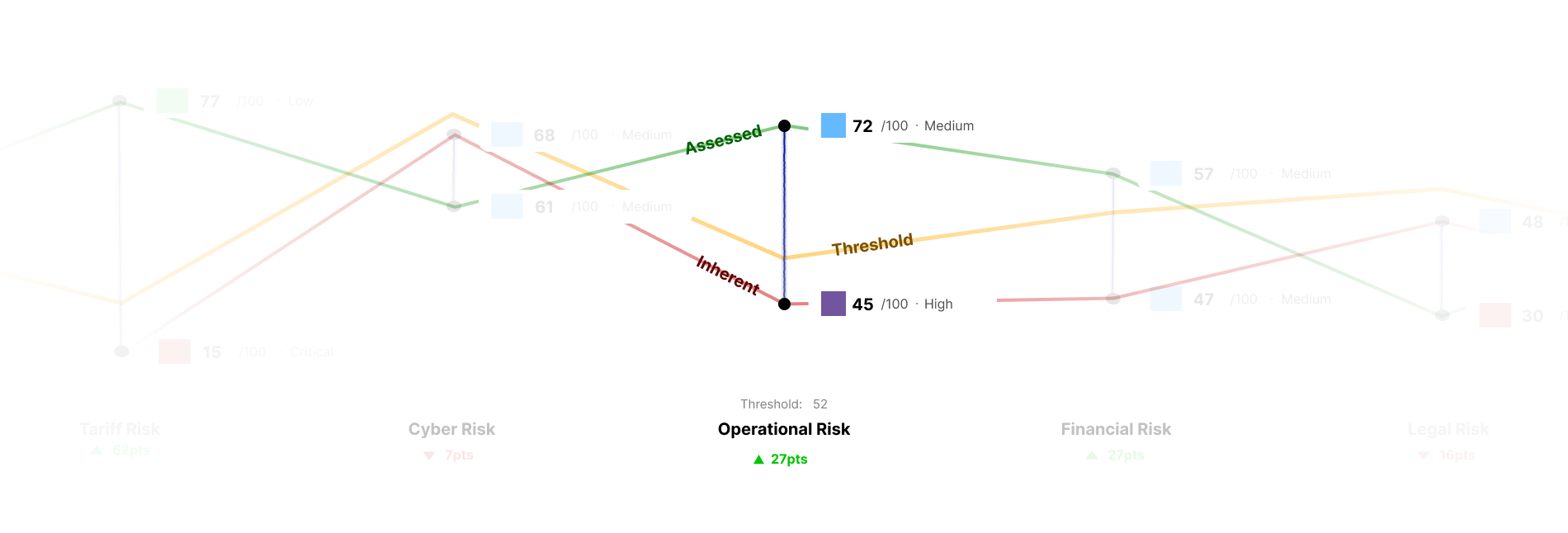

The Residual Risk Profile provides decision makers with a clear indication of where risks remain above threshold. It now a business decision to proceed or not. Based on the information provided and the risk exposures, decision makers can make an informed, timely decision. A strong Supplier Scoring Model increases the objectivity of upstream actions making decision easier and improved.

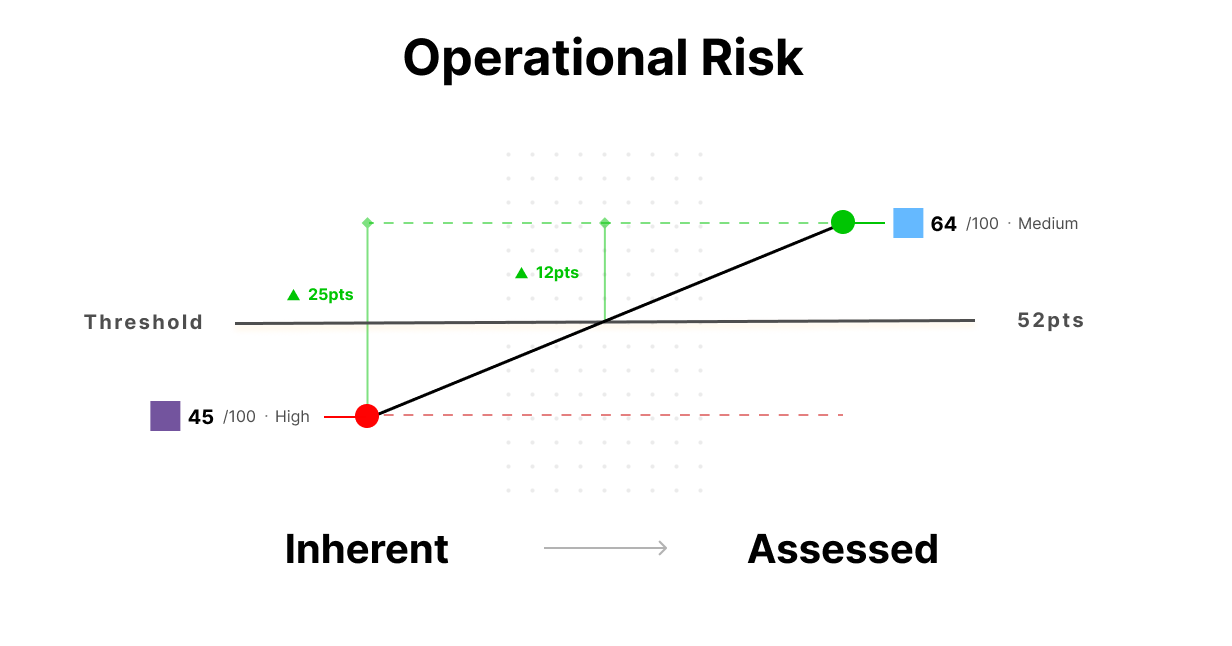

The risk profile of a supplier at the decision point should clearly reflect impacts of mitigation efforts to highlight improvements or regressions in risk exposure, and how the current status compares to your acceptable risk baseline.

What Insights do Supplier Risk Scoring Models Provide?

The most important insight obtained from a Supplier Risk Scoring Model is the assessment of risk exposure. This relates to the remaining residual risk after factoring in mitigations.

The relationship between Inherent, Threshold and Residual Risk Scores.

These insights allow you to make informed decisions on the type of supplier you want to do business with. Even if a supplier is assessed as having heightened risk in certain areas, sometimes that risk can be acceptable when considering business requirements. Accurate, early inherent risk evaluations are essential to making this decision quickly and with extended confidence.

Fortunately, Supplier Residual Risk Scores are usually satisfactory and do not require further action. Depending on the ‘interval’ (the difference between the threshold and the Residual score), different management and ongoing mitigations efforts can be applied. For example, a small interval for Operational Risk might result in a mitigation strategy that requires re-assessment of the supplier for Operational Risk more frequently.

Monitoring how these assessments are tracked is also important. If the same base model is used for evaluation, isolated factors can have their effects measured. These trends allow you to consider and implement further supplier management risk mitigation measures – further strengthening your supplier-base.

You may survive a single supplier risk eventuating, but what if multiple happen at once?

How can you Identify Risky Suppliers?

The higher the risk exposure, the greater the chance that supplier will turn into a ‘bad apple.’ A bad apple spoils the bunch, and more than one bad apple can destroy your business.

Bad apples can be identified by suppliers that are marked as having a high Residual risk, despite mitigation efforts.

Sometimes however, this is the nature of the supply and will be accepted for large upside benefit. This is a decision that the business needs to make and further emphasizes the strong risk-data requirements.

Suppliers that expose a higher risk can have that risk specifically managed, and mitigation can be attempted. If there is an alternative with a more favorable risk profile, the supplier can be replaced. When suppliers have no clear alternatives, additional auditing or risk-mitigation steps are appended to the risk assessment workflow.

How you can Build a Risk Model or Upgrade your Existing One

It is important to build these relationships in software that allows for automated inputs and consumable outputs. Essential to its operation is a configurable, schedulable, and org-structure conscious workflow engine. It is critical that versions and roles are maintained either by the tool, or with a third-party management system. Risk assessments and observability are best served when integrated into the same system. Central to any implementation is a strong document management system that allows you to configure questions, and extract answers for reporting and query-tooling. There are further efficiencies and considerations that can or must be established into a system like this, such as malware-detection for documents, AI assistance, and text-extraction tooling for certificate verifications.

The most effective implementation is to have these features built into a comprehensive front-door supplier management software like IQX Business Solution’s Supplier Online. Explore more using the button below!

Related Posts

If you enjoyed reading this, then please explore our other articles below: